Air Vent Manufacturing: An Industry Overview

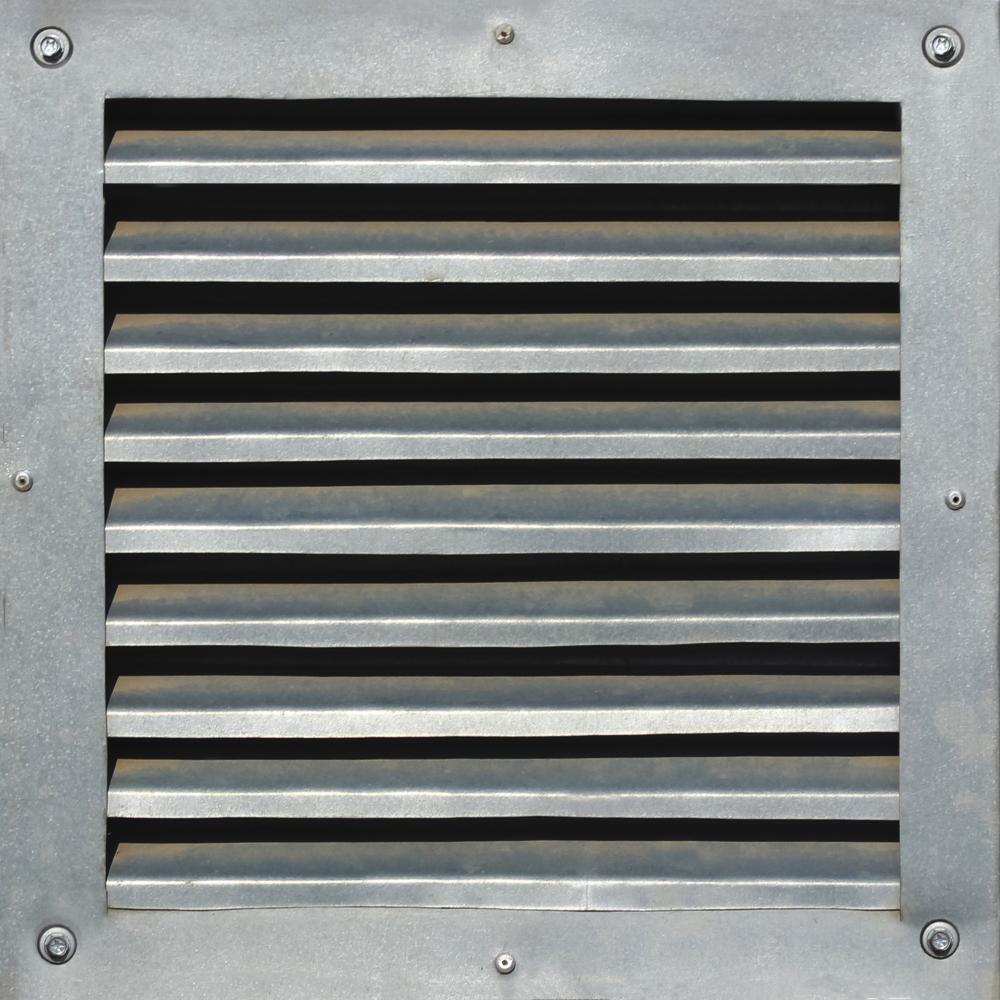

In the realm of air vent manufacturing, attention to detail is paramount. Over the past few decades, innovations have transformed the industry, making it more efficient and precise. My experience at Quench-Air has taught me that crafting a high-quality vent system requires understanding both the materials and the specific needs of different applications, such as MRI quench vent systems.

Materials such as stainless steel and aluminum are popular choices due to their durability and resistance to corrosion. However, the choice of material often depends on the specific requirements of the installation environment. At Quench-Air, we frequently tailor vent systems to accommodate unique demands, ensuring safe and effective venting solutions that align with each client’s specifications.

Our expert team, specifically trained in manufacturing and installation, plays a crucial role in maintaining our reputation as a leader in the industry. Their skill and professionalism ensure that every project is executed with precision and care.

Customization in Air Vent Manufacturing

Customization is at the heart of effective air vent manufacturing. Over the years, I’ve witnessed how tailored solutions can drastically improve system efficiency and safety, particularly in specialized setups like MRI units. Quench-Air’s ability to customize vent systems stems from a deep understanding of each client’s requirements, coupled with our extensive experience across diverse industries.

Our Cryogen Vent Systems are crafted with careful attention to detail, enabling us to provide solutions that are not only effective but also reliable. By working closely with our clients, we can ensure that the vent systems we deliver meet their precise specifications, down to the finest detail.

Customization goes beyond just the design phase. It involves providing flexible shipping options and offering round-the-clock customer support, which ensures that our clients receive prompt assistance whenever needed. This commitment to flexibility and support is a hallmark of our service.

Our commitment to customization extends to our installation process as well. By eliminating the need for field welding, we streamline the installation, reducing potential complications and saving valuable time and resources for our clients.

Efficiency and Innovation in Air Vent Manufacturing

Efficiency in air vent manufacturing is achieved through a combination of innovative design and meticulous execution. At Quench-Air, we pride ourselves on our use of cutting-edge technology and processes, ensuring that every vent system we produce meets the highest standards of quality and performance.

From initial design to final installation, each step is guided by an unwavering commitment to excellence. Our innovative approach has allowed us to develop vent systems that are not only efficient but also environmentally conscious, helping to reduce emissions and promote cleaner air quality.

Our team’s dedication to continuous improvement means we are always exploring new ways to enhance our manufacturing processes. This pursuit of excellence ensures that our clients receive the most advanced and reliable vent systems available.

Customer-Centricity in Air Vent Manufacturing

Putting customers at the center of our operations is not just a philosophy; it’s a practice that drives everything we do at Quench-Air. From the initial inquiry to post-installation support, our focus remains steadfast on ensuring customer satisfaction through every stage of the project.

Immediate responses and quick shipping options are integral to our customer service approach. We understand the urgency that often accompanies air vent requirements, especially in critical applications like MRI units. Our same-day shipping programs are a testament to our commitment to meeting our clients’ needs promptly.

Our team is always ready to offer expert advice and support, whether it’s a simple query or a complex problem. Such dedication to customer service is what sets Quench-Air apart in the air vent manufacturing industry.

Feedback from our clients is invaluable in helping us refine our processes and improve our offerings. By listening and responding to their needs, we continue to expand and enhance the services we provide in the air vent manufacturing sector.

Unique Approaches to Industrial Air Vent Production

Industrial Air Vent Production is a fascinating field that combines engineering prowess with creative solutions to meet diverse client needs. At Quench-Air, we have honed our expertise over decades, focusing specifically on quench vent systems for critical applications like MRI units. Our approach to Industrial Air Vent Production is to prioritize client requirements while ensuring the highest safety and efficiency standards. Every system we produce is tailored to fit specific operational demands, thereby eliminating the need for field welding during installation–a feature that underscores our commitment to operational efficiency.

Our extensive experience in Industrial Air Vent Production has equipped us with unique insights into the challenges of crafting reliable vent systems. For instance, handling cryogenic materials requires precision engineering to address the complexities of helium venting. By leveraging cutting-edge technology, we can offer not only standard solutions but also custom arrangements to address any unique fabrication needs clients might have. This adaptability has allowed us to serve industries on five different continents, demonstrating the global applicability and reliability of our products.

One innovative aspect of our industrial air vent solutions is the integration of quick and reliable shipping options, including same-day services. These capabilities ensure that our clients experience minimal downtime and maximum efficiency, which is crucial in high-stakes environments like medical facilities. Our commitment to prompt service sets us apart in the competitive landscape of Industrial Air Vent Production.

Personalized Solutions and Global Reach

Industrial Air Vent Production at Quench-Air is not just a technical endeavor; it’s a personalized journey tailored to meet the distinct needs of each client. Our team of experts meticulously plans each vent system, taking into consideration factors such as installation site requirements, client preferences, and potential challenges specific to each project. This detailed planning ensures that every vent system is as unique as the client it serves, without compromising on safety or performance standards.

The commitment to personalization is complemented by our global reach, allowing us to adapt our expertise to diverse regulatory environments and operational challenges. Shipping projects to continents around the globe requires a flexible and knowledgeable approach, which has become a hallmark of our Industrial Air Vent Production. This international experience enriches our understanding and enables us to bring the best practices from various regions into every project we undertake.

In terms of customer service, our after-hours availability and immediate response to engineering queries ensure that clients feel supported throughout the entire process. Whether it’s providing rapid quotes or ensuring quick confirmation of sizing calculations, our focus remains on delivering a seamless experience that emphasizes reliability and customer satisfaction.

Incorporating anecdotal evidence into our Industrial Air Vent Production processes allows us to continuously improve and innovate. Learning from varied installations, such as custom cryogen vent assemblies for MRI units, we are consistently refining our systems to offer even greater efficiency and safety. Through these experiences, we have crafted a unique place in the industry, characterized by our ability to meet complex challenges with simple, effective solutions.

Advanced Technologies in Industrial Vent Systems

In the dynamic field of Industrial Air Vent Production, adopting advanced technologies is essential to staying ahead in the industry. At Quench-Air, we pride ourselves on integrating state-of-the-art solutions such as Cryogen Vent Waveguides and Quench Vent Flanges, which are vital for safe helium gas venting in MRI machines. These components are designed with precision to ensure no leakage and maximum operational safety, which is crucial for facilities where the margin for error is minimal.

Our systems are engineered to eliminate the need for field welding during installation, a feature that significantly reduces installation time and costs while enhancing safety. This technological edge is a testament to our commitment to quality and efficiency in Industrial Air Vent Production. By leveraging our vast experience and state-of-the-art technologies, we continually strive to push the boundaries of what is possible in vent system manufacturing.

Moreover, the implementation of customizable fabrication arrangements enhances the versatility of our vent systems. This customization is not just superficial but is integrated down to the minutest detail, allowing clients to modify systems as per their operational needs without compromising on quality or safety. Such innovations are the products of decades of accumulated experience and a deep understanding of our clients’ unique requirements in Industrial Air Vent Production.

Our focus on utilizing advanced technologies ensures that we are not only meeting but exceeding industry standards, thereby solidifying our reputation as a leading provider. The technology-driven approach we take in Industrial Air Vent Production is designed to anticipate future challenges and equip our clients with systems that stand the test of time.

How much does it cost to make a vent?

The cost of manufacturing an air vent can vary significantly based on several factors, including the materials used, size and complexity of the design, and any customization required to meet specific client needs. At Quench-Air, we specialize in crafting tailored vent systems for MRI units, which are highly specialized and require precise engineering to ensure safety and efficiency. These specialized systems can be more costly due to the advanced materials and technology involved. However, our commitment is to provide high-quality workmanship at a reasonable price. Typically, costs can range from a few hundred to several thousand dollars per unit, depending on the requirements. We work closely with clients to provide accurate quotes and ensure transparency throughout the process. If you’re considering a custom vent solution, reach out for a detailed quote that matches your specific needs.

What materials are used for air vents?

The choice of materials for air vents is critical to their performance and longevity. At Quench-Air, we primarily use materials like stainless steel and aluminum due to their durability, resistance to corrosion, and ability to withstand various environmental conditions. These materials are particularly important in specialized applications, such as MRI quench vent systems, where the venting of helium gas requires robust and reliable construction. Stainless steel, for example, offers excellent corrosion resistance and strength, making it ideal for demanding environments. Additionally, aluminum’s light weight and good thermal conductivity can be advantageous in certain contexts. We always tailor material selection to the specific requirements of the installation environment, ensuring optimal performance and safety for each vent system.

What is the difference between an air vent and an air duct?

Understanding the difference between air vents and air ducts is essential for anyone involved in HVAC systems. Air vents are the visible components that cover the openings of the air distribution system, allowing air to flow into a room or space. They are typically adjustable and can be designed to direct airflow in specific ways. On the other hand, air ducts are the conduits or passages used to deliver and remove air as part of the ventilation, heating, and air conditioning systems. They are often hidden within walls or ceilings and are responsible for carrying air between the HVAC unit and the air vents. At Quench-Air, we focus on crafting efficient vent systems tailored for specific applications, ensuring that airflow is managed safely and effectively. The proper integration of vents and ducts is crucial for optimal system performance.

What is the 1 300 rule for ventilation?

The “1 300 rule” is a guideline used in the ventilation industry to determine the appropriate venting area for a given space, ensuring adequate air exchange and preventing issues such as moisture buildup or poor air quality. According to this rule, for every 1 square foot of attic ventilation area, there should be 300 square feet of attic floor space. This ratio helps maintain balanced airflow, which is crucial for the longevity and efficiency of the building’s ventilation system. At Quench-Air, we apply these kinds of standards and principles to design our vent systems, ensuring they meet the specific needs of our clients’ projects. If you’re exploring a new ventilation project and wonder how this rule might apply, consider contacting a specialist who can provide tailored advice for your unique situation.

What unique methods are used in Industrial Air Vent Production?

At Quench-Air, our approach to Industrial Air Vent Production is distinguished by our commitment to efficiency and customization. One of our unique methods includes the elimination of field welding during installation. Instead, our systems are designed for ease of assembly on-site, reducing potential complications and installation time. Additionally, we integrate advanced technologies such as Cryogen Vent Waveguides and Quench Vent Flanges to ensure safe and effective venting, especially in sensitive environments like MRI units. These innovations are part of our ongoing efforts to push the boundaries of what is possible in vent system manufacturing. If you’re interested in learning more about our production methods and how they might benefit your next project, feel free to reach out to our team.

How does Quench-Air approach custom air vent solutions?

Customization is at the heart of Quench-Air’s philosophy. We understand that each client’s needs are unique, especially in critical applications like MRI units. Our approach involves working closely with clients to ensure every vent system is meticulously planned and tailored to their specific requirements. This involves considering factors such as installation environments, operational challenges, and client preferences. Our team is skilled in crafting solutions that are not only effective but also reliable and efficient. We also offer flexible shipping options, including same-day services, to meet the urgent needs of our clients. If you’re considering a custom air vent solution, we invite you to explore the possibilities with Quench-Air, where expertise meets personalization in every project.

Resources

- Environmental Protection Agency (EPA) – The EPA is responsible for protecting human health and the environment by enforcing regulations related to air quality and emissions.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) – ASHRAE provides resources and guidelines for the design and maintenance of HVAC systems, including air vents.

- Occupational Safety and Health Administration (OSHA) – OSHA sets and enforces standards to ensure safe and healthy working conditions, including regulations related to ventilation systems.

- American National Standards Institute (ANSI) – ANSI oversees the development of standards for various industries, including those related to air vent manufacturing and installation.