A Closer Look at Cryogen Vent Fabrication

The field of Cryogen Vent Fabrication involves crafting intricate systems that ensure the safe expulsion of gases like helium from MRI machines. This process requires a delicate balance between precision engineering and practical application, especially considering the high-stakes environments these systems operate in. At Quench-Air, we’ve honed our expertise over 30 years, developing a process that not only meets but exceeds industry standards.

Our approach to Cryogen Vent Fabrication involves creating tailored solutions for each client. We understand that no two MRI setups are identical, so our systems are customized to meet specific demands, from venting waveguides to specialized flanges. This customized fabrication results in a seamless integration, ensuring functionality while reducing the likelihood of operational issues. It’s this attention to detail that has solidified our reputation as leaders in the field.

Tailored Solutions for MRI Units

One of the challenges with venting in MRI units is the need for precise gas evacuation without room for error. The process of Cryogen Vent Fabrication is crucial here, as it minimizes risk and enhances operational efficiency by eliminating potential hazards associated with gas buildup. By focusing on custom-built systems, Quench-Air ensures that helium is vented safely and efficiently, maintaining the integrity of the MRI machine and the safety of the surrounding environment.

Our systems offer a no-welding installation process, which reduces on-site complexities and minimizes installation time. This approach not only ensures safety but also allows for rapid deployment–essential in situations where time is of the essence. By prioritizing ease of installation and reliability, we make it possible for healthcare settings to maintain continuous MRI operation without undue interruption.

With our global reach, having successfully shipped projects to five continents, Quench-Air is well-versed in the diverse needs of international clients. This experience enables us to cater to various regulatory environments and technical requirements, ensuring our Cryogen Vent Fabrication solutions are both compliant and cutting-edge.

Expertise and Customer Support

Our commitment to expertise is mirrored in our dedication to customer support. At Quench-Air, we provide immediate engineering and submittal support, ensuring our clients have access to the information and assistance they need at every stage of the project. This hands-on approach has proven invaluable, especially in situations where quick decision-making is crucial.

Our after-hours availability is a testament to our customer-first philosophy. We understand the critical nature of healthcare operations, and thus provide round-the-clock support to address unexpected challenges. It’s this level of service that has made us a trusted partner in the industry, offering peace of mind to those who depend on us for their Cryogen Vent Fabrication needs.

In addition to our standard offerings, we provide customization options that allow clients to tailor vent systems to their specific needs. Whether it’s adjusting sizing calculations or modifying vent arrangements, our flexibility ensures each project is executed to the highest standard, meeting both client specifications and regulatory requirements.

The Impact of Innovation in Cryogen Vent Fabrication

Innovation is at the heart of Quench-Air’s approach to Cryogen Vent Fabrication. We continually seek new methods and technologies to enhance the efficiency and safety of our vent systems. This forward-thinking attitude ensures we remain at the forefront of the industry, offering solutions that are not just current but also anticipatory of future needs.

By focusing on continuous improvement and embracing novel techniques, we enhance our system designs, making them more robust and user-friendly. Our commitment to innovation is not just about staying competitive–it’s about setting new benchmarks for what can be achieved in Cryogen Vent Fabrication, ultimately benefiting our clients and their patients.

As we look to the future, Quench-Air is dedicated to pushing the boundaries of what’s possible in vent fabrication. Our goal is to continue delivering solutions that protect both technology and human safety, ensuring the continued advancement and reliability of MRI units worldwide.

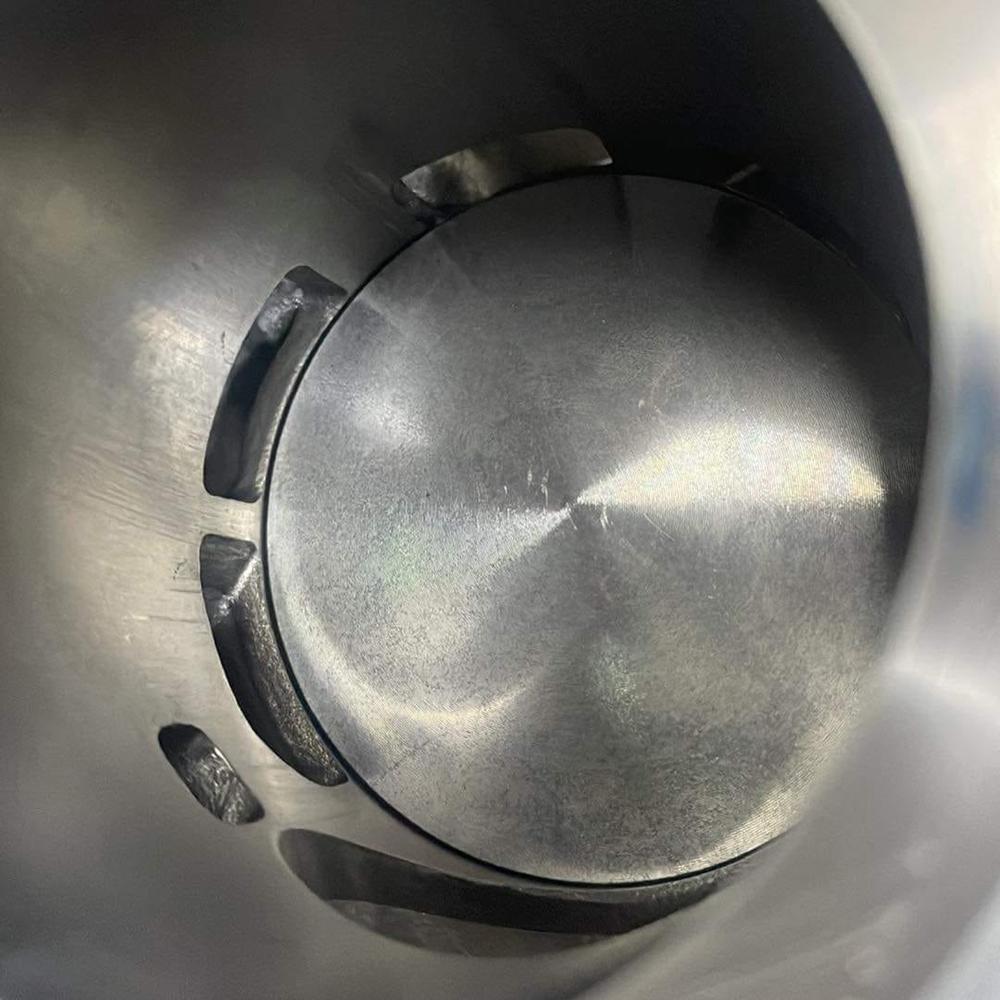

Custom Cryogen Vent Assembly Overview

The Custom Cryogen Vent Assembly is a critical component in the safe operation of MRI machines, acting as a conduit for venting helium gas. This assembly is known for its precision engineering, ensuring effective pressure release while maintaining structural integrity. At Quench-Air, we pride ourselves on delivering excellence through customized solutions designed to cater to the unique requirements of each client.

In my years of working with Quench-Air, the standout feature has been the meticulous attention to detail in our fabrication process. Each Custom Cryogen Vent Assembly is crafted by experts who deploy cutting-edge techniques and rigorous quality checks, ensuring that every unit adheres to the highest industry standards.

These assemblies are not only about functionality but also about flexibility. By choosing Quench-Air, clients benefit from a system that requires no field welding during installation, simplifying the process and saving time. This level of customization allows for easy integration with existing infrastructure, making it a preferred choice among industry professionals.

Design and Manufacturing Insights

The design phase of a Custom Cryogen Vent Assembly at Quench-Air is a collaborative process, involving a synergy between our engineers and clients. Our team employs advanced CAD software to develop detailed models, allowing stakeholders to visualize the final product and make necessary adjustments before fabrication commences. This ensures that every assembly is perfectly tailored to each project’s specifications, eliminating guesswork and maximizing efficiency.

During manufacturing, we utilize state-of-the-art machinery and precision tools, which facilitates high-quality output with minimal error margins. The craftsmanship involved in creating each component ensures that assemblies are robust, reliable, and capable of handling the extreme conditions they are subjected to in MRI environments. Over the years, this meticulous approach has garnered Quench-Air a reputation for durability and performance that clients have come to trust.

Our commitment to innovation is also evident in our use of sustainable practices. Quench-Air is constantly exploring new materials and techniques that not only enhance the performance of our Custom Cryogen Vent Assembly but also reduce environmental impact. This forward-thinking mindset allows us to stay ahead of trends and continue offering groundbreaking solutions to our global clientele.

Feedback from our clients often highlights the smooth transition from design to production. The efficiency with which our team operates ensures quick turnaround times and consistent quality, making us the go-to provider for Custom Cryogen Vent Assembly needs across various continents.

Quench-Air Experience and Customer Insights

My experience at Quench-Air underscores the importance of strong customer relationships and responsive service. One of the most rewarding aspects is the direct feedback we receive from satisfied clients worldwide. These insights drive us to continuously improve our processes and offerings, ensuring we meet and exceed expectations.

Client-centricity is at the heart of Quench-Air’s operations. We focus on offering Custom Cryogen Vent Assemblies that are not only technically superior but also backed by exceptional customer service. Our team is available for consultations and support, providing immediate responses to inquiries and ensuring seamless project execution. This dedication to customer care is reflected in our repeat business and long-standing partnerships with leading industry players.

The real-world success stories shared by our clients are a testament to the reliability and effectiveness of our solutions. Stories of reduced downtime, improved safety measures, and enhanced operational efficiencies reflect the positive impact that a well-designed Custom Cryogen Vent Assembly can have.

At Quench-Air, our goal is to transform the way cryogen vent systems are perceived and utilized, ultimately contributing to the safe and efficient operation of MRI facilities. Through ongoing collaboration and innovation, we aim to deliver solutions that not only meet but redefine the standards of our industry.

What is Industrial Cryogen Vent Construction?

Industrial Cryogen Vent Construction plays a pivotal role in safely managing cryogenic gases that are often used in various applications, from healthcare to energy. This process involves designing and building systems that efficiently vent excess cryogen gases, preventing pressure build-up that can lead to hazardous conditions. In the context of MRI units, the management of helium, a common cryogen, requires specialized vent systems tailored to handle its unique properties.

Installing these systems demands a specific expertise to ensure that all components work seamlessly together, hence minimizing risks associated with cryogenic operations. The construction itself includes assembling components like Cryogen Vent Waveguides and Quench Vent Flanges, ensuring they are tightly integrated into the overall system. The objective is to achieve optimal performance without compromising safety or integrity.

Through Industrial Cryogen Vent Construction, entities like Quench-Air provide high-quality venting solutions that enhance operational efficiency. Their extensive experience supports custom-builds that align with client specifications, particularly in sectors using MRI technology. Their global reach, proven by successful projects across five continents, showcases the effective application of their expertise in cryogen vent systems.

Key Components of Cryogen Vent Systems

Custom-Built Components

Quench-Air’s cryogen vent solutions offer tailor-made components designed to fit the exact needs of each application. With detailed design and precision engineering, they manufacture elements like Cryogen Vent Assemblies that match specific MRI unit requirements. This precision contributes to enhanced safety and efficiency in gas venting operations.

Ease of Installation

A standout attribute of Quench-Air’s systems is their commitment to ease of installation, eliminating the need for field welding. This makes their systems not only safer but also quicker to implement, allowing for minimal downtime during the installation phase. Such streamlined processes are crucial in environments where continuous operation is essential, like healthcare facilities.

Comprehensive Support

Quench-Air’s dedication to customer satisfaction is evident in their all-encompassing support structure. They provide immediate responses to inquiries, offer quick shipping options, and have a proactive stance on engineering and submittal processes. Their post-sale customer service is a testament to their commitment to quality and reliability in Industrial Cryogen Vent Construction.

Customization and Flexibility

One of the less frequently discussed aspects of cryogen vent systems is their adaptability. Quench-Air excels in offering customization options that cater to diverse industrial applications, highlighting their flexibility in design and implementation. By focusing on individual client needs and varying operational environments, they ensure each system optimally supports the client’s application and safety requirements.

The Impact of Cryogen Vent Systems on Industries

Industrial Cryogen Vent Construction is not just about installing equipment; it significantly impacts the operational efficiency and safety standards across industries. Facilities utilizing these systems often experience higher safety metrics due to effective venting solutions that prevent the hazardous buildup of gases. In healthcare, for instance, reliable vent systems are crucial to maintaining the functionality and safety of MRI units.

Beyond immediate benefits, the long-term impact of these systems can be profound. By preventing potential incidents and maintaining operational integrity, they allow industries to focus on core functions without disruption. This efficiency ripple effect can be seen in increased production uptime, cost savings on repairs and maintenance, and ultimately, improved output and service delivery.

Moreover, the innovations in cryogen vent systems, particularly those undertaken by leaders like Quench-Air, enable industries to adapt to evolving challenges with future-proof solutions. Their commitment to continuous improvement and customization ensures that as industry demands change, their systems remain at the forefront of engineering and safety standards.

From a personal perspective, as someone who has worked with industrial cryogen systems, the advancements made by companies like Quench-Air in customizing and implementing these vent systems continue to impress. Their ability to blend technical excellence with customer-centric approaches sets a high bar for the industry, one that benefits myriad sectors reliant on cryogenic technologies.

How does cryogen vent fabrication impact MRI unit safety and efficiency?

Ensuring the safe expulsion of helium gas from MRI units is crucial, as helium buildup can lead to dangerous pressure levels. At Quench-Air, our cryogen vent systems are meticulously designed to mitigate such risks, focusing on safety and efficiency. Our systems facilitate the smooth release of helium, enhancing the MRI’s operational reliability and patient safety. Since our fabrication is specifically tailored to each setup, we can adapt to unique requirements, allowing MRI units to operate without unexpected interruptions. This ensures that healthcare professionals can focus on patient care without being concerned about the technical integrity of their equipment. Have you considered how an upgraded vent system might further optimize your MRI operations?

What material is used for cryogen vent pipes?

The choice of materials for cryogen vent pipes is a pivotal aspect of the system’s performance and safety. Typically, stainless steel is the preferred material due to its excellent strength and resistance to low temperatures and corrosive environments. At Quench-Air, we employ high-grade stainless steel for our vent pipes, capitalizing on its durability and reliability. This material ensures long-lasting performance and minimizes maintenance needs, which aligns with our goal to provide efficient, cost-effective solutions for our clients. Would switching to stainless steel vent pipes be a beneficial consideration for your facility?

What material is used for MRI quench vent?

In MRI units, quench vents must be constructed from materials that can withstand both the low temperatures and the high pressures involved during a quench event. Stainless steel is again the go-to material here due to its robust properties. Our quench vents at Quench-Air are designed with precision, utilizing stainless steel to ensure resilience and dependability even under extreme conditions. The consistency of using high-quality materials across our systems helps maintain the reliability and safety of MRI operations. Have you evaluated your quench vent materials recently to ensure they meet the latest safety standards?

What is a cryogen in MRI?

A cryogen in MRI refers to a substance, like liquid helium, used to cool the superconducting magnets within the machine. This cooling is essential for the magnets to maintain their superconductivity, which is crucial for generating the magnetic fields necessary for MRI imaging. The challenge lies in safely managing these cryogens, as they need to be vented efficiently to prevent pressure buildup. In scenarios where helium expands due to warming, our systems are designed to manage the release effectively, maintaining the integrity of the MRI unit. How often do you assess the efficiency of your cryogen management systems?

How does a quench vent work?

A quench vent is specifically designed to handle the rapid expulsion of helium gas from an MRI unit when superconducting magnets lose their magnetic field. This situation, known as a quench, requires immediate and safe gas venting to avoid excessive pressure buildup. Our quench vents at Quench-Air work by providing a controlled pathway for the helium to escape, maintaining pressure balance and preventing damage to the MRI unit or harm to nearby personnel. The efficiency of this system is vital in ensuring the safe operation of MRI facilities. Have you experienced any quench events, and how did your current system perform in response?

How does Quench-Air ensure its cryogen vent systems meet global standards?

Quench-Air takes a comprehensive approach to ensuring its cryogen vent systems adhere to global standards. We maintain a robust quality control process that includes rigorous testing and compliance checks aligned with international regulations. Additionally, our global experience, having completed projects on five continents, provides us with insights into diverse regulatory environments and technical specifications. This allows us to design systems that are not only compliant but also cutting-edge. Our commitment to quality and safety is reflected in every project we undertake. Are there specific global standards you need to meet with your cryogen vent systems?

What are the main considerations when designing custom cryogen vent assemblies?

Designing custom cryogen vent assemblies involves several key considerations. Safety is paramount, meaning the system must prevent any hazardous gas buildup while ensuring robust performance under extreme conditions. At Quench-Air, we focus on precision engineering and customization to address each client’s specific needs, factoring in variables like facility layout and operational requirements. Our systems are also designed for ease of installation, eliminating the need for field welding and reducing downtime. How do you prioritize safety and efficiency in your current systems, and what improvements are you looking to implement?

Why is ease of installation important in cryogen vent systems?

The ease of installation in cryogen vent systems is crucial for minimizing disruptions and reducing potential hazards during setup. Quench-Air prioritizes no-welding installations, which simplifies the process, allowing for quick and safe deployment. This approach is particularly beneficial in healthcare settings, where time is of the essence. By reducing installation complexity, we ensure that our systems are operational in a timely manner, supporting uninterrupted MRI functionality. How does your facility handle system installations, and could there be advantages in adopting a no-welding approach?

How do industrial cryogen vent systems impact operational efficiency?

Industrial cryogen vent systems significantly enhance operational efficiency by preventing gas buildup and ensuring continuous equipment functionality. In sectors like healthcare, where MRI units are critical, the efficiency of these systems can directly impact patient care quality. At Quench-Air, our systems are designed to integrate seamlessly with existing infrastructure, fostering smooth operations while minimizing maintenance needs. By focusing on robust design and ease of integration, we help facilities concentrate on their core functions without disruption. What operational challenges are you currently facing that might be alleviated by an improved vent system?

What are the key components of cryogen vent systems?

A well-designed cryogen vent system comprises several essential components, including vent pipes, waveguides, and flanges. At Quench-Air, each part is custom-built to meet specific client requirements, ensuring optimal performance and safety. Our systems also emphasize ease of installation and comprehensive support, ensuring that all components work together seamlessly for effective gas expulsion. Each component’s design contributes to the overall efficiency and reliability of the system. How do you evaluate the performance of your current system components, and are there areas that require improvement?

How can innovation in cryogen vent systems benefit industries?

Innovation in cryogen vent systems can profoundly impact industries by enhancing safety, efficiency, and adaptability. For instance, Quench-Air’s focus on new technologies and materials allows us to offer solutions that are not only current but also future-ready. As industries evolve, having adaptable systems in place ensures that operations can seamlessly accommodate new challenges. This proactive approach supports better safety metrics and operational continuity. How does your organization integrate innovation into its operational strategy, and what benefits have you observed?

Resources

- National Institute of Standards and Technology – Official website of the National Institute of Standards and Technology providing resources on standards, measurements, and technology.

- World Health Organization – Homepage of the World Health Organization offering information on global health issues and initiatives.

- U.S. Department of Energy – Official website of the U.S. Department of Energy providing resources on energy policies and technologies.

- U.S. Food and Drug Administration – Homepage of the U.S. Food and Drug Administration offering information on food, drugs, and medical devices regulation.