Cryogen Vent Manufacturing

In the realm of MRI technology, Cryogen Vent Manufacturing plays a pivotal role in ensuring both safety and operational efficiency. The process involves creating specialized vents that effectively manage the release of helium gas used to cool MRI magnets. Such a system is essential for preventing potential hazards associated with gas leaks, which can disrupt the magnetic field and damage the equipment or worse, pose risks to human safety.

Furthermore, state-of-the-art Cryogen Vent Manufacturing is integral to maintaining the longevity and performance of MRI units. By facilitating the smooth evacuation of cryogenic gases, these systems help avoid pressure buildup, which can cause mechanical failures. As a result, hospitals and diagnostic centers can operate with confidence in their equipment’s reliability and safety.

Quench-Air, an industry leader in this field, has consistently demonstrated expertise in crafting systems that integrate seamlessly with various MRI models. This adaptability is a testament to their understanding of the nuanced requirements of different medical environments, ensuring that each system is custom-tailored for optimal performance.

Innovations in Cryogen Vent Design

Recent advances in Cryogen Vent Manufacturing have ushered in a wave of innovations aimed at enhancing operational efficiency and user convenience. One of the most notable developments is the introduction of systems that eliminate the need for field welding during installation, significantly reducing setup time and potential installation errors. This innovation ensures that installations are quicker and maintain structural integrity without compromising on safety.

Additionally, customizable vent designs have become a hallmark of modern Cryogen Vent systems, allowing for seamless integration with existing MRI units and site-specific configurations. This flexibility empowers medical facilities to optimize their infrastructure without costly overhauls, making high-quality cryogenic vent solutions more accessible.

Quench-Air’s commitment to continual improvement is evident in their rapid response time for quotes and immediate engineering support, demonstrating a deep understanding of their clients’ need for speed and reliability. Their ability to provide tailored solutions positions them as a frontrunner in the competitive landscape of Cryogen Vent Manufacturing.

Moreover, Quench-Air impresses with their capacity to swiftly ship solutions across continents, emphasizing their global reach and competence in navigating complex logistical challenges. Such innovations reflect their dedication to excellence in both product and service delivery.

Quench-Air Expertise and Global Reach

With over three decades of experience, Quench-Air has carved a niche in the Cryogen Vent Manufacturing industry by providing unparalleled expertise and service. Their extensive experience has enabled them to develop a deep repository of knowledge concerning the intricacies of cryogenic vent systems, ensuring that each client receives a solution that perfectly matches their needs.

Quench-Air’s proficiency is not confined to local boundaries; their successful execution of projects across five continents showcases their ability to manage and deliver complex projects globally. This global presence is bolstered by their after-hours customer service, offering clients peace of mind knowing that expert help is just a call away, regardless of time zone differences.

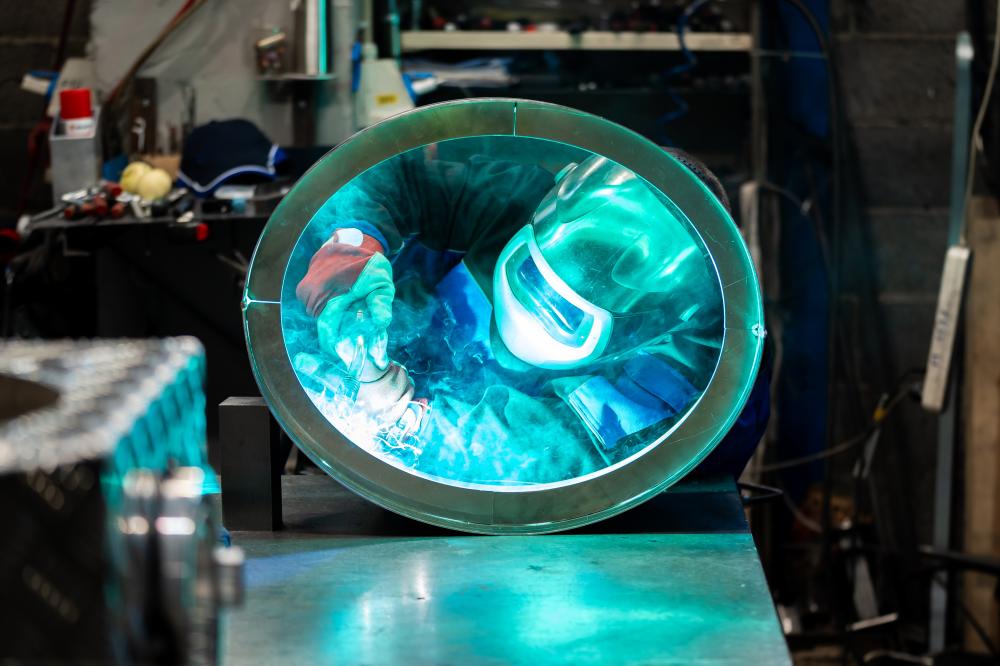

Their dedication to high-quality workmanship is reflected in every project, from initial design to on-site implementation. Clients can rest assured that each Quench-Air vent system is crafted with meticulous care and precision, adhering to the highest industry standards. This commitment has established Quench-Air as a trusted name in the field of Cryogen Vent Manufacturing, known for reliability and excellence.

Innovations in Cryogen Vent Design

Quench-Air has redefined Custom Cryogen Vent Production by emphasizing innovative design solutions tailored specifically to the medical imaging sector. Their approach to cryogen vent systems focuses on seamless integration with MRI units, prioritizing safety and functionality. With over 30 years in the industry, Quench-Air’s team of specialists combines extensive technical knowledge with practical insights gained from working on an international scale.

A key feature of their service is the production of cryogen vent waveguides, which ensures the safe and efficient disposal of helium gas. The waveguides are crafted with precision to align with diverse MRI machine requirements, minimizing risks associated with helium exposure. By utilizing advanced materials and engineering techniques, Quench-Air enhances the durability and reliability of these components.

The elimination of field welding during installation is another notable innovation by Quench-Air, streamlining the setup process and reducing potential hazards. Components such as quench vent flanges and assemblies are pre-fabricated for efficiency, ensuring that each element fits perfectly upon delivery. This meticulous attention to detail exemplifies Quench-Air’s dedication to excellence in Custom Cryogen Vent Production.

Global Reach and Customization

Quench-Air’s capability to ship projects to five continents highlights their status as a global leader in Custom Cryogen Vent Production. Their expansive reach is matched by a commitment to customization, offering clients the flexibility to design vent systems that meet specific operational needs. This adaptability is vital in accommodating the unique challenges of different MRI systems and regional safety standards.

The company’s prompt and thorough service is a cornerstone of its operations. Quench-Air provides immediate engineering support and submittal documentation, ensuring projects remain on schedule. Their readiness to respond to urgent requests is demonstrated through quick shipping options, including same-day programs, which are invaluable for time-sensitive installations.

Quench-Air’s commitment to customer satisfaction is further evidenced by their willingness to customize any fabrication arrangement. This bespoke approach allows clients to modify existing designs or create entirely new configurations, addressing the nuances of their specific operating environments. This flexibility is a testament to Quench-Air’s mastery in Custom Cryogen Vent Production and their responsiveness to client needs.

Customer support extends beyond regular business hours, reflecting Quench-Air’s dedication to maintaining open communication channels. This accessibility ensures that any concerns or adjustments needed during the fabrication or installation phase are swiftly addressed, fostering a collaborative and trust-based relationship with their clientele.

Ensuring Safety and Efficiency

Safety and efficiency are central to Quench-Air’s philosophy in Custom Cryogen Vent Production. Their systems are meticulously designed to safeguard both equipment and personnel from cryogenic hazards. The seamless venting of helium gas is essential to preventing pressure build-up in MRI rooms, thus protecting both the machinery and the health of medical staff and patients.

Quench-Air’s commitment to quality workmanship ensures that all components meet rigorous industry standards. The use of high-grade materials and precise manufacturing processes guarantees the longevity and reliability of their cryogen vent systems. This quality assurance provides peace of mind to clients investing in critical medical infrastructure.

The expertise of Quench-Air’s team is a significant asset in identifying and implementing the best practices for vent system design and installation. Their extensive training and experience allow them to anticipate potential challenges and develop proactive solutions, streamlining the entire process from initial consultation to final installation.

Overview of Industrial Cryogen Vent Solutions

Industrial Cryogen Vent Solutions play a crucial role in the safe handling and regulation of helium gas in MRI machines. At Quench-Air, with over three decades of dedicated experience, they deliver custom-built systems that emphasize safety and efficiency. Every quench vent system is designed to cater to specific client requirements, ensuring optimal performance without the need for field welding during setup.

These solutions are not just about venting; they encompass the design and fabrication of essential components such as Cryogen Vent Waveguides, Quench Vent Flanges, and Cryogen Vent Assemblies. With the ability to customize these parts, Quench-Air provides Industrial Cryogen Vent Solutions that ensure both safety and reliability. Every project reflects their commitment to quality workmanship and client satisfaction, reinforced by their global reach with successful implementations across five continents.

Their presence in the industrial sector is marked by a proactive approach, offering immediate quotes and rapid shipping options. This responsiveness is coupled with adept engineering and customer support, setting a benchmark in the industry for Industrial Cryogen Vent Solutions.

Benefits of Customized Solutions

Tailored Systems for Unique Needs

Customizing quench vent systems means that each client receives a solution specifically tailored to their unique requirements. With Industrial Cryogen Vent Solutions by Quench-Air, customization is not a luxury but a standard offering. This ensures that even the most unique and challenging situations are addressed with precision and expertise. Their team excels in fabricating components that seamlessly integrate into existing structures, providing flexibility and peace of mind.

Professional Craftsmanship and Support

Quench-Air stands out with its commitment to professionalism and ongoing client support. Their experts are trained in the intricacies of vent manufacturing and installation, ensuring a seamless process from design to on-site implementation. The company is also known for its innovative engineering approaches, significantly reducing installation time, and thus minimizing disruption to ongoing operations. This attention to detail and customer engagement underscores the value of their Industrial Cryogen Vent Solutions.

Global Reach and Expertise

With a portfolio of successful projects across diverse geographical locations, Quench-Air demonstrates the adaptability and robustness of their solutions. Clients worldwide trust them for their capability to deliver on time and within budget, thanks to their scalable production and shipping processes. Industrial Cryogen Vent Solutions from Quench-Air ensure that no matter where the project is located, the same high-quality and reliable standards are maintained.

The Human Touch in Industrial Solutions

In a field dominated by technical prowess, the human element can sometimes be overlooked. Yet, it’s the cornerstone of Quench-Air’s approach to Industrial Cryogen Vent Solutions. By integrating personal insights and experiences into their operations, they create a unique bond with clients. Anecdotes from past projects often guide new solutions, illustrating the blend of knowledge and empathy that drives their innovative processes.

In one instance, a client faced an unusual challenge involving existing infrastructure obstacles. Through meticulous planning and collaboration, Quench-Air engineers devised a creative workaround, transforming a potential setback into a successful venture. Such experiences highlight the importance of human ingenuity coupled with advanced technology in delivering outstanding solutions.

With Quench-Air at the helm, Industrial Cryogen Vent Solutions are not just about meeting technical specifications but also about making meaningful connections through each project. Their approach ensures that every client feels heard and valued, fostering long-term partnerships built on trust and shared success.

What material is used for cryogen vent pipes?

The choice of material for cryogen vent pipes is critical due to the extreme temperatures involved in handling cryogenic gases like helium. Typically, stainless steel is the preferred material because of its excellent thermal conductivity and resistance to both high and low temperatures. Stainless steel also offers superior mechanical properties and durability, which is essential for safety and efficiency in cryogen vent systems. At Quench-Air, we prioritize using high-grade stainless steel to ensure our systems can handle the rigors of constant use while maintaining structural integrity.

What material is used for MRI quench vent?

For MRI quench vents, the material must withstand the rapid expansion of helium gas during a quench event. We use stainless steel, similar to other cryogenic applications, which provides the necessary strength and durability to handle such extreme conditions. The smooth surface of stainless steel also minimizes resistance, ensuring efficient gas flow and safe venting. With our experience at Quench-Air, we’ve found that stainless steel is ideal for maintaining safety and efficiency in MRI environments.

What is a cryogen in MRI?

In the context of MRI, a cryogen is a cooling agent used to maintain the superconducting state of the MRI magnets. Helium is the most commonly used cryogen due to its exceptionally low boiling point of 4.2 Kelvin. This allows the MRI magnets to remain superconductive, enhancing imaging quality by sustaining a stable magnetic field. At Quench-Air, we emphasize the significance of proper cryogen management systems to ensure both the safety and longevity of MRI equipment. Understanding the role of cryogens is vital for anyone involved in MRI machine maintenance or operation.

How does a quench vent work?

A quench vent is designed to safely discharge helium gas from an MRI system in the event of a magnet quench. This process involves the rapid release of helium to prevent damage to the magnets and surrounding equipment due to pressure build-up. Our systems at Quench-Air are engineered to facilitate smooth, efficient venting without the need for field welding during installation. By incorporating advanced technologies and designs, we ensure that the venting process is both effective and reliable, safeguarding both equipment and personnel.

What are common misconceptions about cryogen vent manufacturing?

One common misconception is that cryogen vent manufacturing involves simple piping systems. In reality, it’s a complex process requiring precise engineering to ensure safety and efficiency. Another myth is that all cryogen vent systems are identical, but each must be customized to the specific needs of the MRI unit and facility. At Quench-Air, we emphasize that proper system design and materials are crucial for safe operation. If you’ve encountered any misconceptions or have questions, feel free to discuss them with us, and we can provide insights based on our extensive industry experience.

How are custom cryogen vent solutions developed?

Developing custom cryogen vent solutions involves a collaborative approach where we assess the unique requirements of the client’s facility and MRI equipment. Our engineers at Quench-Air work closely with medical professionals to tailor systems that fit specific operational parameters and site constraints. From initial consultation to final installation, every step focuses on safety, efficacy, and integration. Custom solutions allow facilities to optimize performance without costly infrastructure overhauls. Are you interested in exploring a tailored solution for your facility? We welcome such inquiries to further discuss personalized options.

What are the key components of industrial cryogen vent solutions?

Industrial cryogen vent solutions consist of several crucial components, including Cryogen Vent Waveguides, Quench Vent Flanges, and Assemblies designed to handle helium gas safely. Each component plays a role in facilitating efficient venting by reducing pressure and ensuring the structural integrity of the vent system. At Quench-Air, our systems are crafted with precision to meet rigorous industry standards, and we incorporate advanced materials to enhance durability and performance. We take pride in delivering reliable solutions that underscore our commitment to quality workmanship.

How does global reach impact custom cryogen vent manufacturing?

Global reach in custom cryogen vent manufacturing means being able to deliver tailored solutions across different continents while adhering to regional standards and requirements. At Quench-Air, our international presence allows us to implement solutions quickly and efficiently, even in disparate geographical contexts. This capability not only ensures timely deliveries but also maintains quality and consistency in our offerings. Are you interested in how our global operations could benefit your facility? We’d be happy to discuss our international projects and how they inform our local practices.

How does Quench-Air integrate the human touch into its operations?

At Quench-Air, we believe that personal interaction and experience are key to successful cryogen vent solutions. By maintaining open lines of communication and fostering relationships, we ensure our clients feel valued and understood. We often draw from past project anecdotes to tailor solutions that meet unique client needs, exemplifying our approach where technology meets empathy. If you have a unique challenge or requirement, don’t hesitate to reach out. We strive to provide not only technical solutions but also personal support and understanding.

Resources

- U.S. Food and Drug Administration – The FDA oversees the safety and effectiveness of medical devices, including MRI technology.

- National High Magnetic Field Laboratory – A research laboratory focused on advancing high magnetic field science and technology.

- Centers for Disease Control and Prevention – The CDC provides information on health and safety guidelines for medical facilities.

- National Institute of Standards and Technology (NIST) – NIST sets standards for measurement and promotes innovation in science and technology.

- World Health Organization (WHO) – The WHO provides global health guidance and resources for medical professionals.