A Customized Approach to Custom Cryogen Vent Production

In the specialized world of Custom Cryogen Vent Production, the ability to tailor solutions for each client is paramount. Quench-Air has perfected this approach, offering bespoke quench vent systems that meet the unique specifications of MRI units. Their services encompass a wide array of components such as Cryogen Vent Waveguides, Quench Vent Flanges, and Cryogen Vent Assemblies. With over three decades of experience, they understand the intricacies involved in safely venting helium gas and tailor each system to avoid the need for field welding during installation.

One distinctive feature of Quench-Air’s services is their commitment to immediate responses for quotes and sizing calculations. Their efficiency doesn’t stop at the drawing board; they offer quick shipping options, including same-day programs that cater to urgent needs. This efficiency has enabled Quench-Air to establish a global presence, with projects delivered to five continents, underscoring their capability and reliability in Custom Cryogen Vent Production.

Craftsmanship and Attention to Detail

The meticulous craftsmanship at Quench-Air sets them apart in the realm of Custom Cryogen Vent Production. Their expert team is adept at ensuring that every facet of vent manufacturing and installation meets the highest standards. By focusing on details, they’re able to guarantee not only the functionality but also the longevity of their products. Each Quench Vent System is not only custom-built for performance but also designed to be installed seamlessly without requiring field welding.

Customers seeking professional and cost-effective solutions will find solace in Quench-Air’s approach. Their dedication to quality workmanship at a reasonable price makes them a preferred choice for many in the industry. The company’s ingrained professionalism and streamlined processes ensure that each project is executed smoothly from start to finish, offering clients peace of mind and reliability.

A Personal Touch in Custom Cryogen Vent Production

Amid the technical precision required in Custom Cryogen Vent Production, Quench-Air adds a personal touch that enhances their client relationships. Their team is not only trained in technical expertise but also in customer interaction, ensuring that each client feels valued and heard. This approach boosts confidence and builds long-lasting partnerships, as clients know they can rely on Quench-Air for support beyond the standard business hours.

Serving a wide array of clients across various sectors, Quench-Air excels in adaptability. Their customizable fabrication arrangements demonstrate a flexibility that caters to individual requirements, ensuring that each system is as unique as the client’s needs. Whether it’s immediate engineering support or intricate submittal processes, their commitment to customer service remains unwavering.

Having successfully delivered numerous projects globally, Quench-Air’s ability to combine technical prowess with a personal touch ensures they remain a leader in the industry. For anyone in need of effective and tailored quench vent solutions, their reputation as a trusted provider stands strong, making them an ideal partner for Custom Cryogen Vent Production challenges.

Customization and Versatility

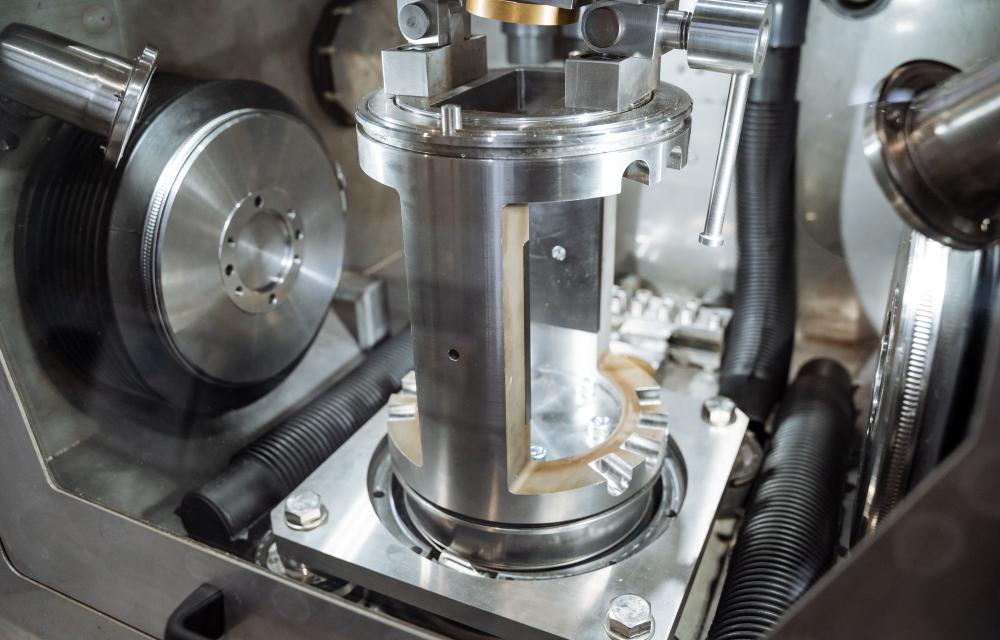

The art of Cryogen Vent Manufacturing is steeped in both precision and adaptability. At Quench-Air, the process begins with client consultation, ensuring each system meets unique specifications. This customized approach is vital, particularly when dealing with MRI units that demand specific venting solutions.

What makes Quench-Air stand out is its ability to provide a range of components such as Cryogen Vent Waveguides, Quench Vent Flanges, and Cryogen Vent Assemblies. Each part is meticulously crafted, integrating seamlessly into the broader system. This attention to detail ensures that the entire installation operates efficiently, without the need for field welding, thus minimizing on-site challenges.

The versatility of Quench-Air’s offerings extends to shipping capabilities as well. Having successfully delivered projects across five continents, their efficient logistical strategies guarantee timely delivery. Whether it’s a standard order or an expedited request, their shipping solutions are designed to accommodate the needs of every client.

Commitment to Quality and Safety

At the heart of Cryogen Vent Manufacturing is a steadfast commitment to safety and quality. Quench-Air’s vent systems for MRI machines are designed to ensure the safe evacuation of helium gas. This critical function is achieved through innovative designs that eliminate the need for field welding, significantly reducing the potential for installation errors.

The expertise of Quench-Air’s team plays a fundamental role in maintaining high standards. With over 30 years of experience, their professionals bring a wealth of knowledge to each project. This expertise is coupled with immediate engineering and customer support, offering clients peace of mind knowing they are in capable hands.

Adding an additional layer of assurance, Quench-Air provides quick shipping options and same-day quotes. This responsiveness is vital in an industry where timing can be crucial. The company’s ability to confirm sizing calculations promptly further solidifies its reputation as a reliable partner in Cryogen Vent Manufacturing.

Moreover, Quench-Air’s dedication is evident in their after-hours customer service, emphasizing their commitment to support clients whenever necessary. This proactive approach ensures that each client receives the attention and service they deserve, making Quench-Air a trusted choice in the industry.

Innovative Approaches and Client-Focused Service

Quench-Air’s unique approach to Cryogen Vent Manufacturing is characterized by innovation and a client-centered focus. This begins with their fabrication process, which allows for complete customization of Quench Vent Systems. The ability to tailor every aspect of a system to fit specific requirements is a testament to their expertise and commitment to client satisfaction.

Their client-focused service extends to comprehensive support, from initial consultations through to on-site installation. Each project is managed with precision, ensuring seamless interaction between various components and the broader system. This level of detail and coordination is essential in achieving a successful outcome.

Quench-Air also excels in providing educational resources for clients, allowing them to make informed decisions. This transparency empowers clients, fostering a collaborative environment that enhances project outcomes. It is this blend of innovation, expertise, and client commitment that sets Quench-Air apart in the Cryogen Vent Manufacturing industry.

The ability to adapt and evolve is central to Quench-Air’s philosophy. By continually refining their strategies and embracing new technologies, they remain at the forefront of the industry. This forward-thinking mindset ensures that they can meet the ever-changing demands of the market, delivering exceptional service and high-quality products time and again.

Innovative Approaches in Industrial Cryogen Vent Solutions

Quench-Air offers cutting-edge Industrial Cryogen Vent Solutions, perfectly designed to meet the needs of modern MRI units. With over three decades of experience, Quench-Air has honed its ability to create custom-built systems that ensure safe and effective helium gas evacuation without the need for field welding. This approach not only reduces potential hazards during installation but also lowers costs significantly by minimizing the need for additional labor. These tailored solutions reflect the company’s commitment to addressing unique client requirements, providing a safer and more efficient environment.

One of Quench-Air’s key strengths lies in its ability to offer quick and precise sizing calculations that allow clients to benefit from optimal solutions tailored to their specific demands. This precision helps in reducing unexpected costs and delays, which are often a concern in industrial settings. Their industry-leading expertise has led to the successful shipment of over 1050 systems to five continents, showcasing their capacity to handle both local and global projects with equal finesse.

In addition to their technical prowess, Quench-Air emphasizes seamless customer experiences by offering immediate responses for quotes and engineering submittals. Their team is available even after hours to provide assistance and support, ensuring that client needs are addressed promptly. By choosing Quench-Air’s industrial cryogen vent solutions, businesses can rely on a partner that prioritizes both safety and customer satisfaction.

Quench-Air Custom Solutions and Services

Quench-Air stands out in the industry with a variety of offerings that cater to the complex needs of cryogen vent system installations. Their range includes Cryogen Vent Waveguides, Quench Vent Flanges, and Cryogen Vent Assemblies, all of which are crafted with precision to match diverse operational demands. By focusing on high-quality workmanship, Quench-Air ensures that each component is built to withstand the rigorous conditions of cryogenic environments.

A deep understanding of industrial requirements allows Quench-Air to offer solutions that eliminate site-specific challenges, such as field welding. This not only streamlines the installation process but also minimizes risk and project downtime. Their flexible shipping options, including same-day programs, underscore their dedication to meeting tight project schedules and delivering unparalleled convenience to their clients.

The company’s commitment to providing comprehensive Industrial Cryogen Vent Solutions is evident in their customizable fabrication arrangements. Clients can work with Quench-Air’s dedicated team to design systems that perfectly match their operational needs while maintaining compliance with industry standards. This collaborative approach ensures that each system is not just an installation, but a fully integrated part of the client’s operational framework.

Quench-Air’s reputation for reliability and quality is built on decades of delivering exceptional service and robust solutions. For any business seeking premium industrial cryogen vent solutions that prioritize safety and efficiency, Quench-Air emerges as the ideal partner.

Global Reach and Industrial Cryogen Vent Solutions Expertise

The global reach of Quench-Air and its expertise in Industrial Cryogen Vent Solutions is underscored by successful project deployments on five continents. This experience positions them uniquely to understand and navigate the varying regulatory and environmental landscapes that affect vent system installations worldwide. Leveraging their international experience, Quench-Air adeptly addresses the challenges presented by different climates and geographic conditions, ensuring optimal performance in diverse settings.

Quench-Air also leads in technological advancements, continually refining their processes to incorporate the latest industry innovations. Their commitment to staying ahead of the curve is reflected in their robust product lineup, which is both cutting-edge and rooted in practical applications. This blend of innovation and practical experience positions Quench-Air as a front-runner in providing reliable Industrial Cryogen Vent Solutions to businesses of all sizes, from local enterprises to multinational corporations.

What material is used for cryogen vent pipes?

When it comes to designing cryogen vent pipes, particularly for applications involving MRI units, we at Quench-Air opt for materials that offer both durability and resistance to extreme temperatures. Stainless steel is a preferred choice due to its ability to withstand the low temperatures of cryogenic gases like helium. The material’s resistance to corrosion and structural integrity under intense pressure ensures a long lifespan and reliable performance.

In our extensive experience, we’ve found that using high-quality stainless steel helps in minimizing maintenance costs and enhancing the safety of the entire venting system. Furthermore, stainless steel facilitates seamless integration with other system components, which is crucial in avoiding unnecessary complications during installation.

Have you ever wondered how the choice of material might impact the efficiency of a venting system? Feel free to reach out to us at Quench-Air; we’re happy to discuss how our material selections can benefit your specific requirements.

What material is used for MRI quench vent?

MRI quench vents are critical for safely venting helium gas, and here at Quench-Air, we primarily use stainless steel for this application. The choice is driven by the material’s robustness and ability to maintain structural integrity even under sudden changes in temperature and pressure, which are common during a quench incident.

Stainless steel also prevents the formation of ice plugs, which can be a concern with other materials. This ensures that the vent remains clear and functional during an emergency, providing a reliable passage for rapidly escaping gases. Choosing the right material is not just about compliance; it’s about ensuring patient and staff safety by minimizing risks during MRI operations.

What considerations do you think are essential when selecting materials for cryogenic applications? Let’s explore the topic further if you’re interested in a deeper dive!

What is a cryogen in MRI?

A cryogen, in the context of MRI, typically refers to liquid helium used to cool the superconducting magnets. This cooling is necessary to ensure that the magnets maintain their superconducting state, which is essential for generating the powerful magnetic fields required in MRI imaging.

At Quench-Air, we understand the critical role helium plays in this process. Our custom quench vent systems are designed to handle the safe and efficient evacuation of helium gas in the event of a quench–when the superconductivity is lost, and the helium rapidly boils off. Our designs prioritize safety and efficiency, ensuring that your MRI units operate smoothly without unexpected downtimes or hazards.

Have you ever been curious about the science behind MRI technology? The intricate dance of temperatures and magnetic fields is fascinating, and we’re always excited to discuss how our systems contribute to this incredible technology.

How does customization benefit MRI vent systems?

Customization is at the heart of what we do at Quench-Air, and it provides significant benefits when it comes to MRI vent systems. By tailoring each system to the specific needs of our clients, we ensure optimal performance and safety. Customization allows us to consider the unique layout and requirements of each MRI facility, leading to a more efficient installation process and a system that integrates seamlessly with existing infrastructure.

Moreover, customized systems are designed to eliminate the need for field welding, which not only reduces installation time but also minimizes potential safety hazards. Each project comes with its own set of challenges, and our ability to adapt and innovate ensures that we provide solutions that not only meet but exceed client expectations.

Are there specific challenges you’re facing with your current MRI vent systems? We’d love to hear about them and show you how our expertise could turn those challenges into opportunities.

Resources

- U.S. Food and Drug Administration – The FDA ensures the safety of food, drugs, medical devices, and more, providing regulatory guidance for industries like cryogen vent production.

- National Center for Biotechnology Information – NCBI offers valuable resources on biomedical and genomic information relevant to industries working with cryogenic materials.

- National Institute of Standards and Technology – NIST provides standards, measurements, and calibration resources that are crucial for quality control in cryogen vent manufacturing.

- Occupational Safety and Health Administration – OSHA sets and enforces workplace safety standards, ensuring that industries like cryogen vent production maintain a safe working environment.