Customized Quench Vent Solutions

The realm of Industrial Quench Vent Solutions is an intricate one, especially concerning MRI units. As someone who has worked at Quench-Air, our expertise in manufacturing and installing Cryogen Vent systems is unrivaled. With over three decades of experience, we understand that each client has unique requirements and therefore, we offer bespoke quench vent systems tailored to these needs. Each system is a testament to our commitment to excellence and safety, ensuring optimal venting of helium gas without the need for field welding.

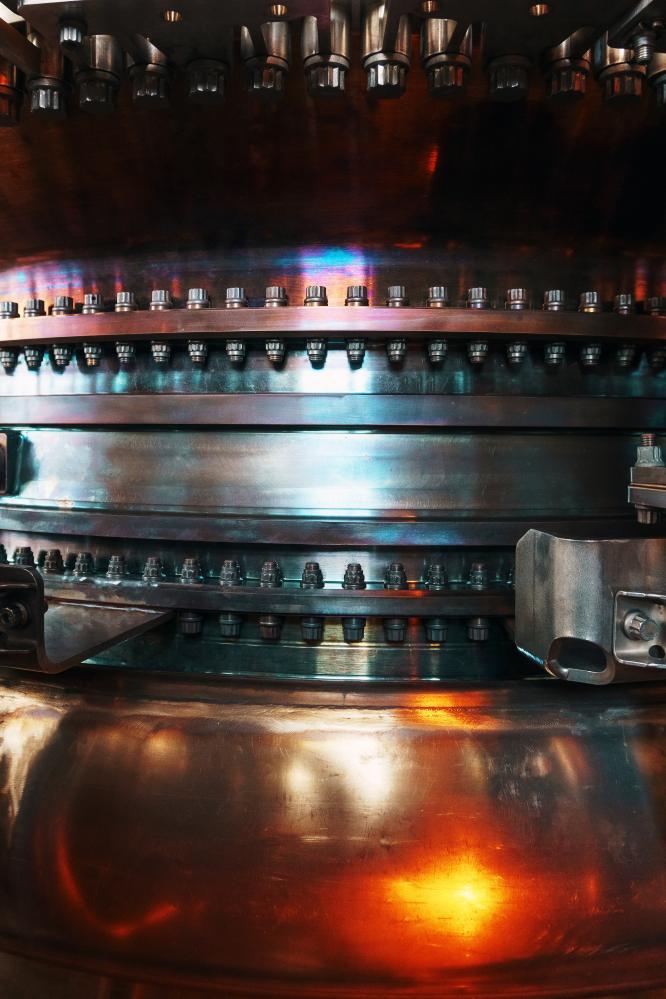

One of the features that sets us apart is our ability to customize fabrication arrangements. From Cryogen Vent Waveguides and Quench Vent Flanges to Cryogen Vent Assemblies, each component is meticulously crafted to align with the client’s machinery. This bespoke approach is not just about creating a fit-for-purpose solution, but also about enhancing the longevity and performance of the MRI units while offering a seamless installation experience.

Quality and Innovation

In the world of custom Quench vent systems, quality and innovation walk hand in hand. At Quench-Air, we pride ourselves on the craftsmanship and innovation that underpin our work. Our vent systems are designed for efficiency and safety, crafted to ensure that the venting process is smooth and hassle-free. This innovation-driven approach has enabled us to successfully dispatch projects to five different continents.

The professional training our experts undergo is rigorous, equipping them with the skills to manage from fabrication to site installation efficiently. This training guarantees that every project is executed with precision and professionalism, something our clientele has come to rely on. By eliminating field welding, we not only mitigate potential risks but also expedite the installation process, saving valuable time and resources for our clients.

It’s essential to note that our commitment to quality isn’t just about the products. It’s engrained in our customer service ethos. We ensure ready support is available, whether it’s through immediate engineering responses or after-hours customer care. Our clients appreciate the peace of mind that comes with knowing we’re just a call away, ready to provide assistance whenever required.

Our same-day shipping program is another testament to our dedication to customer service excellence. This flexibility and promptness ensure that our clients receive their orders swiftly, maintaining downtime to an absolute minimum and allowing them to focus on their core operations.

Global Reach and Efficiency

Quench-Air’s reach across five continents illustrates our capability to adapt and deliver Industrial Quench Vent Solutions globally. Each region presents unique challenges and regulatory environments, and our team is adept at navigating these landscapes to ensure compliance and performance exceed expectations.

Our efficiency in execution is often highlighted by clients who have experienced firsthand the smooth transition from quote to installation. We provide not only the systems but also the peace of mind that comes with knowing that our team is equipped to handle urgent requirements with speed and accuracy.

Expert Insight

The industry of Industrial Quench Vent Solutions is constantly evolving, and staying ahead requires a blend of experience, innovation, and a client-first approach. At Quench-Air, these elements come together to form a robust framework for the services we offer. We’ve carved a niche by not just meeting but exceeding client expectations, constantly setting new benchmarks for quality and service.

Drawing from personal insights gathered throughout my tenure at Quench-Air, the importance of a reliable partner in this industry cannot be overstated. From the initial quote to the final installation, our team’s dedication shines through, making us a favored choice for those seeking top-tier quench vent solutions tailored to their specific needs.

- Immediate engineering and submittal support.

- Same-day shipping programs to reduce downtime.

- Customizable solutions tailored to client specifications.

- Global reach with projects shipped to five continents.

For any organization looking to enhance their MRI systems’ safety and efficiency, trusting a seasoned expert like Quench-Air to deliver unmatched Industrial Quench Vent Solutions is a decision that promises peace of mind and operational excellence.

Importance of Quench Vent Manufacturing

In the specialized world of MRI machines, Quench Vent Manufacturing plays an integral role in ensuring the safety and efficiency of cryogen vent systems. A crucial aspect of this process is the proper venting of helium gas, which occurs when an MRI machine undergoes a quench, a rapid boil-off of helium, to prevent overpressure. At Quench-Air, we recognize the vital responsibility of designing and manufacturing reliable quench vent systems that safeguard both the machinery and its operators.

Over our 30 years of experience, we have discovered that customizing vent systems to meet the unique specifications of each client greatly enhances performance and reliability. Our team prioritizes a seamless process from fabrication to implementation, ensuring that each component, from Cryogen Vent Waveguides to Quench Vent Flanges, is tailored for optimal functionality. This dedication to customization has allowed us to provide effective solutions across five continents.

Innovations in Quench Vent Systems

One of the standout features of Quench-Air’s systems is the elimination of field welding requirements during installation. This advancement not only speeds up the installation process but also reduces potential safety risks associated with on-site welding. Our commitment to innovation drives us to constantly explore new methods to improve the efficiency and safety of our systems.

Our immediate response capabilities are another aspect of our service that our clients greatly appreciate. Whether it’s delivering a quote, confirming sizing calculations, or arranging rapid shipping, we pride ourselves on our responsiveness and ability to meet urgent needs. Our same-day shipping programs further underline our commitment to minimizing downtime for our clients.

The expertise and training of our team are critical to our ability to deliver exceptional quench vent manufacturing solutions. Each member is specifically trained in vent manufacturing and installation, ensuring that our high standards of quality are maintained throughout every project. This focus on training and expertise is a cornerstone of our service, enabling us to offer reliable and effective solutions.

Customization is a key element of our approach, allowing us to provide fabrication arrangements that precisely match each client’s requirements. This flexibility and attention to detail underline our commitment to delivering high-quality workmanship at a reasonable price, reinforcing Quench-Air’s reputation as a trusted leader in the field.

Personal Insights into Quench Vent Manufacturing

Working in the field of Quench Vent Manufacturing has provided us with a wealth of insights and experiences that shape how we approach our work. Having witnessed firsthand the critical importance of reliable quench vent systems, we are deeply committed to delivering solutions that ensure the safety and functionality of MRI units.

Our global reach has afforded us the opportunity to work with diverse clients, each with their own unique challenges and requirements. This diversity keeps us adaptable and constantly learning, as we strive to provide the most effective solutions for each specific situation. It’s this adaptability that has cemented Quench-Air’s place as a leading name in the industry.

Ultimately, our mission is rooted in a passion for overcoming challenges and delivering unparalleled customer service. We remain available after hours and ready to respond to urgent inquiries, reinforcing our commitment to our clients’ needs. For anyone seeking reliable and efficient Quench Vent Manufacturing solutions, Quench-Air remains a provider you can trust.

What material is used for quench vents?

At Quench-Air, we primarily use stainless steel for our quench vents. Stainless steel is favored due to its remarkable ability to withstand the low temperatures associated with helium as well as its corrosion resistance, ensuring longevity and durability. Imagine a scenario where you’re overseeing the maintenance of a delicate MRI unit; the last thing you’d want is a compromised vent system due to material degradation. Our material choice guarantees that reliability is at the forefront of our design.

What material is used for quench piping?

Quench piping at Quench-Air is also manufactured using stainless steel. This choice is crucial as it contends with both thermal and structural demands during the quenching process. Stainless steel’s robustness ensures that the piping can efficiently handle the rapid expulsion of helium gas during a quench, which is a vital safety feature. When setting up an MRI facility, consider how the choice of materials can influence the longevity and safety of the equipment you rely on daily.

What is the code for MRI quench vent?

Typically, the design and installation of MRI quench vents follow specific codes and standards such as NFPA 99, which addresses health care facilities’ requirements. In addition, local building codes and ASME standards might come into play. At Quench-Air, we ensure all our installations are compliant with these codes, helping customers navigate the complex regulatory landscape. It’s always a good idea to discuss with your project manager how these regulations impact your specific setup, ensuring all compliance measures are met.

What is the temperature of the quench vent?

The temperature of a quench vent can be extremely low due to the rapid release of helium gas. Helium is a cryogenic liquid, and its boiling point is at a frigid -268.9°C (-452°F). During a quench, the vent must efficiently handle these low temperatures to prevent any machinery malfunction. Imagine you’re in charge of an MRI facility where safety is paramount. Understanding how extreme temperatures affect your quench system can guide maintenance schedules and risk assessments.

How does customization of quench vent systems benefit the client?

Customization is at the heart of what we do at Quench-Air. By tailoring our quench vent systems to each client’s unique needs, we ensure that the MRI units operate at peak performance with minimal downtime. For instance, a custom system might include specific venting configurations or dimensions tailored to fit into a pre-existing structure without the need for field welding. This approach not only enhances system reliability but also extends its operational lifespan. Have you considered how a customized approach might solve specific challenges in your setup?

What are common misconceptions about the safety of quench venting?

A common misconception is that any vent system can handle the extreme conditions of a quench, which isn’t true. Proper venting is a precision task, requiring a specifically designed system to safely expel helium gas from an MRI. At Quench-Air, our bespoke systems are crafted with this in mind, ensuring both safety and compliance. Think about your current system: is it designed with the precise specifications your facility demands?

What innovations have improved cryogen vent systems recently?

Innovations in cryogen vent systems, particularly at Quench-Air, include eliminating the need for field welding, which streamlines installation and reduces potential safety risks. This advancement not only saves time but also enhances safety during installation. Additionally, our commitment to same-day shipping options reduces downtime, ensuring that facilities can return to operational status promptly. Picture a new facility anticipating its first MRI installation; how relevant do you think these innovations could be to their tight timeline?

Why is quench vent manufacturing important for MRI safety?

The manufacturing of quench vents is crucial because it directly impacts the safety and efficiency of MRI systems. During a quench, the helium used to cool the MRI rapidly evaporates and must be safely discharged. A well-manufactured quench vent ensures this process is controlled, preventing equipment damage and ensuring patient and staff safety. When you’re dealing with sensitive medical equipment, how vital do you find the reliability of each component?

How does immediate engineering support benefit clients using quench vent systems?

Immediate engineering support is invaluable, especially in a critical field like MRI operations. At Quench-Air, our prompt support allows us to quickly address any concerns or changes needed, ensuring the vent systems continue to function optimally. For instance, should you need urgent modifications or have pressing questions about the venting process, our team is ready to assist, reducing any potential operational hiccups. How would having such reliable support impact your operations?

Resources

- U.S. Food and Drug Administration – The FDA oversees regulations related to medical devices, ensuring safety and efficacy in healthcare technology.

- World Health Organization – The WHO provides global guidance and resources on health issues, including medical device safety.

- National Institute of Standards and Technology (NIST) – NIST develops standards to enhance measurement accuracy, including those related to medical equipment.

- International Organization for Standardization (ISO) – ISO sets international standards for quality and safety, including those in the healthcare industry.