MRI Machine Exhaust Systems

MRI Machine Exhaust Systems

In the realm of medical imaging, MRI machines play a crucial role in diagnosing a variety of conditions. However, the operation of these machines involves the use of cryogenic gases such as helium. When an MRI machine undergoes a quench, the sudden release of helium gas can be hazardous. This is where the MRI Machine Exhaust System becomes vital. It ensures the safe expulsion of gases to prevent potential harm to both the equipment and personnel. An effective exhaust system can mitigate risks associated with temperature fluctuations, equipment damage, or even asphyxiation hazards.

Quench-Air, with its extensive 30-year experience, stands out in this field for its high-quality Cryogen Vent systems designed specifically for MRI units. These systems are engineered to handle pressure differentials efficiently, ensuring safe and prompt venting of gases without the need for field welding during installation. Such innovations are crucial in hospitals and imaging centers where safety cannot be compromised.

Components of an Effective Exhaust System

Quench Vents

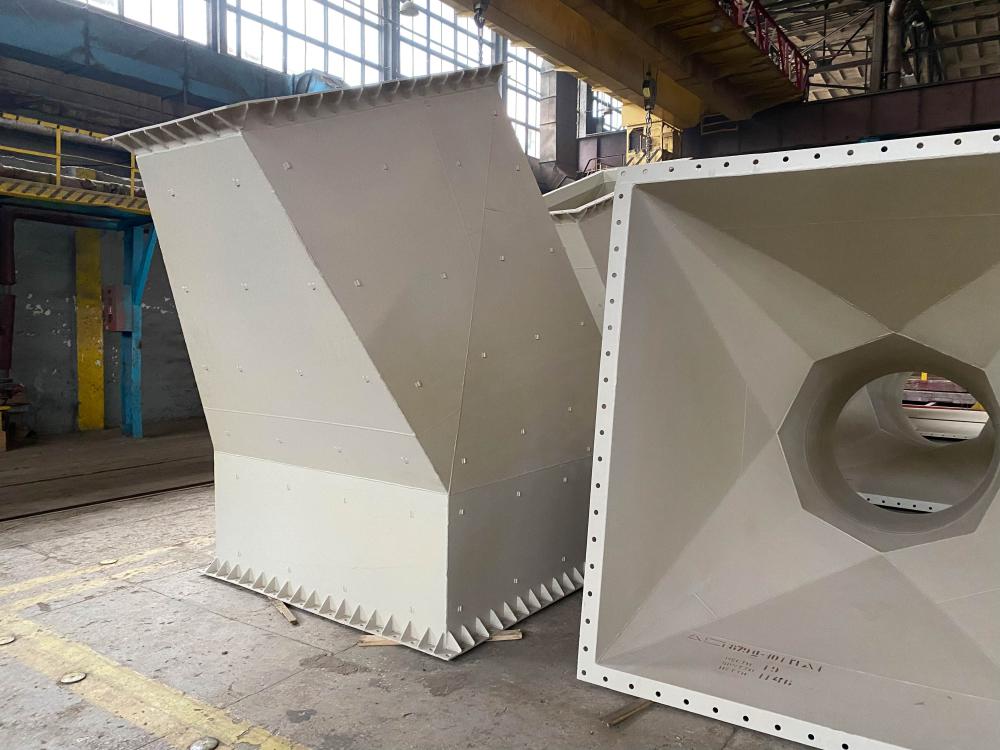

Quench Vents are the cornerstone of any MRI Machine Exhaust System. They are meticulously designed to channel released gases safely out of the facility. Made primarily from durable materials like stainless steel, these vents resist corrosion and ensure longevity, even under extreme conditions. The design of these vents by Quench-Air allows for easy integration with existing systems, enabling a seamless transition during installations or upgrades.

Connection Types and Accessories

An often-overlooked aspect of exhaust systems is the versatility in connection types. Quench-Air provides various options such as flange connections, which allow for secure and stable assembly. Additionally, accessories like waveguides and vent flanges are essential to tailor the exhaust system to the specific demands of the facility. This customization ensures compatibility with different MRI models and configurations, optimizing the efficacy of the exhaust process.

Expertise and Global Reach

Partnering with a supplier like Quench-Air brings the advantage of extensive expertise and a global reach. Their experience in fabricating and implementing MRI Machine Exhaust Systems expands across multiple continents, a testament to their capability and reliability. This global footprint means they are well-versed in navigating diverse regulatory requirements, allowing for a compliant and efficient installation anywhere in the world.

Customers benefit from quick and efficient service, including immediate engineering support and customization options to suit unique project needs. Quench-Air’s team of experts is dedicated to ensuring every aspect of the exhaust system, from design to implementation, meets the highest standards of safety and performance.

Innovations in Exhaust System Technology

Advancements in exhaust technology have significantly enhanced the safety and functionality of MRI Machine Exhaust Systems. One such innovation by Quench-Air is their modular designs allowing for straightforward upgrades and scalability. These systems are designed to accommodate future technological advancements in MRI technology without extensive modifications.

The integration of smart monitoring systems is another leap forward. These technologies provide real-time data on the status of the exhaust system, enabling proactive maintenance and ensuring optimal operation. In an industry where precision and safety are paramount, such innovations offer reassurance and reliability.

In conclusion, choosing the right MRI Machine Exhaust System is imperative. With industry leaders like Quench-Air offering pioneering solutions and expert support, facilities can confidently safeguard their operations and prioritize patient and staff safety. The dedication to innovation and customer satisfaction sets Quench-Air apart as a preferred choice in the market and a trusted partner for any healthcare facility considering MRI installations or upgrades.

Importance of Quench Vent Suppliers

Quench Vent Suppliers play a vital role in ensuring the safety and functionality of MRI systems, which extensively rely on effective venting solutions for optimal performance. At the heart of an MRI unit’s operation lies the need to safely vent helium gas during quench events–an unexpected superconducting transition that could potentially lead to system damage if not properly managed. Quench-Air, as a leader in this field, provides custom-built, ready-to-install Cryogen Vent systems specifically designed to address the unique requirements of each MRI setup, ensuring both safety and efficiency.

With over 30 years of industry experience, Quench-Air specializes in manufacturing comprehensive Quench Vent Systems that eliminate the need for field welding. This reduces on-site labor time and associated risks, benefiting both healthcare providers and their patients. The immediate response with quoting and sizing calculations, paired with the capability to handle projects globally, positions Quench-Air as a reliable partner for hospitals and medical facilities worldwide.

Whether dealing with an emergency or routine installation, the expertise of Quench Vent Suppliers like Quench-Air ensures the seamless integration of critical venting solutions into existing MRI infrastructure. Their proven track record across five continents highlights their ability to cater to diverse international needs without compromising on quality.

Customization and Accessibility

Quench-Air’s commitment to customization and accessibility is evident in their approach to Quench Vent Systems. Unlike many competitors, they offer customizable fabrication arrangements, allowing each solution to be tailored precisely to the client’s specifications. This bespoke service ensures that every MRI unit’s unique challenges are met with the most effective and efficient systems, regardless of complexity or scale.

Accessibility is further enhanced by Quench-Air’s readiness to provide immediate technical support and customer service, even after standard business hours. For clients, this means the assurance of having a knowledgeable partner available to address concerns or answer queries at any time. This commitment to customer support not only enhances client confidence but also ensures that each project can proceed smoothly with minimal disruptions.

For projects requiring swift execution, Quench-Air offers expedient shipping options, including same-day programs, ensuring that critical components arrive exactly when needed. Their ability to meet tight deadlines without sacrificing quality speaks volumes about their operational efficiency and dedication to customer satisfaction.

Expertise and Global Reach

Quench-Air’s vast expertise in the realm of Quench Vent Suppliers is grounded in their comprehensive training programs, which equip their team with specialized knowledge in vent manufacturing and installation. This ensures that each project is executed with precision, from initial fabrication to on-site implementation, underscoring their commitment to high-quality workmanship.

Expanding beyond national borders, Quench-Air’s reach extends to clients across five continents, showcasing their ability to adapt to various regulatory and environmental standards. Their global experience has led to the development of a profound understanding of different market needs, allowing them to deliver tailored solutions that meet international demands.

Their professional approach to vent system fabrication is reflected in every facet of their operations, from meticulous engineering processes to innovative design solutions. Clients seeking a dependable Quench Vent Supplier can trust Quench-Air to provide the expertise and support necessary for successful project completion, no matter where they are located.

Quench-Air’s ability to consistently deliver exceptional results both locally and globally positions them as a favored choice for those in need of reliable Quench Vent solutions. Their long-standing industry presence and extensive client portfolio are testaments to their unwavering commitment to excellence and innovation in the field.

Importance of Quench Pipes in MRI Systems

The marvel of Magnetic Resonance Imaging (MRI) technology hinges on the delicate balance of magnetic fields and super-cooled conditions, making safety a paramount concern. Quench Pipes for MRI are crucial in managing emergencies related to the rapid release of helium gas, which might occur when the machine’s magnetic field is abruptly deactivated. Such instances, though rare, can pose serious hazards if not managed correctly.

To prevent helium from displacing oxygen within the area, Quench Pipes for MRI are meticulously designed to channel the gas safely outside the facility. This ensures the room remains breathable, thus safeguarding both personnel and equipment from potential harm. The efficiency and reliability of these quench systems can’t be overstated, as they provide critical protection in emergency scenarios.

Personal anecdotes in the field stress the importance of proper quench pipe installation and maintenance. An engineer in the industry recalls a scenario where a faulty installation nearly led to a catastrophic failure. Thankfully, routine checks and high-quality materials prevented a disaster, underscoring the essential role these systems play.

Design and Installation of Quench Pipes

Quench-Air, a leader in this field, offers state-of-the-art Quench Pipes for MRI that cater to diverse client specifications without the need for field welding. This innovation speeds up the installation process and enhances safety, avoiding potential pitfalls associated with welding on-site. Their cryogen vent systems stand out for their tailored fit and precise engineering.

The design of Quench Pipes for MRI includes a multitude of components such as Cryogen Vent Waveguides and Quench Vent Flanges. Each piece is crafted to ensure a seamless venting process. The materials used are selected for their strength and durability, ensuring that the system functions optimally under high-pressure quench scenarios.

Professional experiences highlight the value of expertise in the installation process. An installation manager from Quench-Air noted that their team’s rigorous training ensures that each project is completed with the utmost precision and care. This dedication not only meets but often exceeds client expectations, reinforcing Quench-Air’s reputation for excellence.

Global Reach and Customer Support

Quench-Air’s impact is evident in their global reach, having successfully shipped customized Quench Pipes for MRI to five continents. This extensive experience enables them to address a myriad of environmental and logistical challenges unique to each location, providing tailored solutions that meet specific needs.

Their commitment to customer service shines through in their immediate engineering support and flexible fabrication arrangements. Clients can enjoy peace of mind knowing that Quench-Air’s dedicated team is available even after hours, ready to address urgent queries and deliver timely assistance. Their customer-first approach ensures that all installations are as efficient and effective as possible.

Anecdotal evidence from past clients underscores the company’s dedication. One hospital administrator noted how a personalized consultation led to an optimized quench vent solution, demonstrating Quench-Air’s ability to adapt and innovate for superior results. This client-centered ethos makes Quench-Air a trusted partner in MRI safety and functionality.

Emphasizing the importance of quality assurance, Quench-Air’s after-sale support continues to maintain high standards of safety and reliability. Their proactive maintenance strategies and prompt response times have earned high praise from customers worldwide, solidifying their reputation for delivering exceptional service and expertise.

What are the requirements for MRI exhaust?

Ensuring the safety and efficiency of MRI exhaust systems is crucial, as these systems safely expel helium gas during quench events, protecting both equipment and personnel. Requirements include durable materials like stainless steel for corrosion resistance, efficient venting solutions to handle pressure differentials, and the ability for seamless integration with existing systems. At Quench-Air, we ensure our systems meet these standards by providing custom-built solutions tailored to each facility’s specifications, ensuring compliance with local regulations. It’s not just about safety; it’s about creating systems that optimize performance and longevity.

What happens when an MRI machine overheats?

Overheating in MRI machines can occur during a quench event when the superconducting magnet warms up quickly, releasing helium gas. This can lead to equipment damage, temperature fluctuations, and potential safety hazards if not managed properly. At Quench-Air, our Cryogen Vent systems are designed to address these issues quickly and effectively, preventing overheating consequences. Imagine if this situation wasn’t managed well–a hospital could face costly repairs and downtime. By implementing our robust exhaust solutions, we help ensure that healthcare providers can continue delivering uninterrupted patient care, even when unforeseen issues arise.

What makes MRI machines so loud?

You might have noticed the loud noises during an MRI scan, which can be quite startling. This noise is due to the rapid switching of magnetic gradient coils used to create detailed images of the body’s interior. The coils experience intense magnetic forces that make them vibrate, resulting in the characteristic knocking sounds. While this is perfectly normal, it can cause discomfort to patients. We always recommend using ear protection for patient comfort. Exploring new technologies to reduce noise levels can also enhance the patient experience, and it’s an area of innovation we’re keenly interested in supporting through our advancements in exhaust systems.

What are the side effects of MRI quench?

An MRI quench is a sudden release of helium gas due to deactivation of the magnet, often causing a puff of mist and a rise in temperature. Potential side effects include risks of asphyxiation if the gas displaces oxygen and the possibility of equipment damage from abrupt temperature changes. Our focus at Quench-Air is to minimize these risks through our advanced exhaust systems, which efficiently channel the gas outside the facility. By doing so, we help prevent safety hazards and ensure the room remains safe for both patients and staff. How do you feel about the prospect of handling such high-stakes situations? Our team thrives on providing peace of mind in these scenarios.

Why are Quench Vent Suppliers crucial?

Quench Vent Suppliers play a pivotal role in MRI systems by providing solutions that manage the safe expulsion of helium gas during quench events. At Quench-Air, we understand that every MRI setup is unique, requiring vent systems that are both reliable and efficient. Our custom-built solutions ensure that all systems are tailored to individual needs, optimizing safety and performance. Imagine facing a quench without proper vent systems in place–potential damage and safety risks could be overwhelming. That’s why our experience and global reach make us a preferred partner, offering peace of mind to medical facilities worldwide.

Resources

- Mayo Clinic – A reputable source for medical information and healthcare services.

- U.S. Food and Drug Administration (FDA) – Regulatory information on medical devices and healthcare practices.

- World Health Organization (WHO) – Global health information and resources.

- National Institutes of Health (NIH) – Leading research institution for medical advancements and health studies.

- Centers for Disease Control and Prevention (CDC) – Health information and disease prevention resources.